WORK

technical ex

Tesla - My Journey So Far...

Since joining Tesla in November 2020 as an Engineering Technician in Palo Alto, I’ve been deeply involved in advancing sustainable transportation through rigorous testing and innovation. Within three months, I was promoted to Associate Test Engineer in recognition of my contributions to vehicle systems validation.

After a short break, I rejoined Tesla in India, where I supported vehicle durability testing, regulatory inspections, and field operations such as RLDA tests and supercharger site evaluations. These experiences strengthened my adaptability and problem-solving skills in fast-paced environments.

In 2022, I returned to Palo Alto as a Test Engineer, focusing on validating critical components for Models S, 3, X, Y, Semi, and Cybertruck. I later took ownership of coolant loop system validation for Cybertrucl, applying principles of fluid dynamics, pressure control, and reliability engineering to meet demanding performance goals.

Now, as a Senior Test Lead for high-voltage devices—including contactors, fuses, and shunts—I lead testing efforts across Tesla's vehicle and energy platforms. I’ve helped drive standardization, design custom test hardware and fixtures, and ensure efficient, real-world validation to support Tesla’s growth into a more scalable, mature organization.

Throughout my tenure, I've taken pride in overdelivering on Tesla's mission, blending technical expertise with collaborative leadership to push the boundaries of electric vehicle technology.

Skills:

-

Python, LabVIEW, Solidworks, CATIA, 3DX, NIMAX

-

Leadership

-

Reliability Analysis

-

Electromechanical System Design

-

Innovative Problem-Solving

-

Hands-on Engineering

VELORQ Electric Kits

As a co-founder of Velorq, I thrived to give the best service to our customers. With the idea of promoting the use of sustainable energy in a densely populated country like India, we (me and my 'like-minded friend') manufactured electric kits that could be retrofitted on bicycles, bikes and cars. These retrofit kits were custom made as per the requirements of the customer. Selling a kit involved everything from understanding the customers' needs, educating them about the benefits and associated risks of an electric drivetrain, narrowing down on the kit contents and specifications, giving them a time frame for the work and completing other associated paper work, to physically measuring the chassis, designing mounting brackets and battery cabinets, making a chain drive assembly with tensioners, welding the brackets on their bikes, mounting motors, speed sensors and battery chargers and then finally delivering the product after ample quality and safety testing.

At Velorq, I learnt how important it is to use my engineering skills in a way that fascinates people and also helps the world to be a better place.

Skills:

-

5S

-

Lean Six sigma

-

Cost reduction

-

Value stream mapping

-

Just in Time

High Gravity process intensification- Trilok Corporation

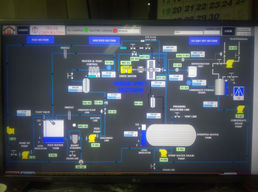

I served as the Assistant Manager at Trilok leading a team of 15 engineers and technicians and was responsible for creating a first-of-its-kind HiGee De-Aeration Plant (separating oxygen from water).

Having hands-on experience in working with machines from a young age resulted in me developing adeptness at identifying smooth synchronous working of various instruments, motors, and pumps. Being able to visualize the translation of a binary command sent by the click of a mouse, into a high-pressure 2-Ton/hour machine working on its own, was one of my most crucial contributions towards proper functioning of the. A PC along with a Siemens PLC and VF drive was programmed to control 7 pumps, a 120 kW heater, a 10 HP motor, 10 analog and digital actuators, and about 12 analog and digital sensors. I also went on to write the user and maintenance manual of the machine. Prompt communication with the higher management, a critical task, which ensured the smooth flow of information within the hierarchy and between engineering, sales, marketing, and supplier departments, was seen to completion by me.

We successfully commissioned the entire unit with an approved SAT, within a short span of 15 days with just 3 technicians, at BPCL research and development facility in Noida, India in 2016 as opposed to the proposed commissioning time of 30 days with the help of 10 engineers. A great learning lesson indeed in the management of precious resources such as money, manpower, and time!

Skills:

-

GD&T

-

PLC programming

-

AutoCAD- Electrical

-

Process automation

-

Team Leader

For more information on what a “Skid based HiGee De-aeration unit” is please refer www.higeetrilok.com

Award- “Key Contributor”

Hybrid Electric Vehicle (HEV)

I was part of a team building a Hybrid Drivetrain for an IC engine powered scooter. What made our idea different was the approach we had taken. Countering the expensive and not so feasible electric vehicles, our aim was to design and develop a retrofit electric kit. A kit that could be installed in any pre-existing IC engine vehicle without major modifications. We were successful in achieving a substantially lower running cost, better performance, and lowering emissions. We believed that this was a better way to enter the EV market and contributing to a greener planet. My role in the team was to design the mechanical structure and integrate it with electronic hardware. Having a strong hand in electronics, and passion in mechanical designing, I was successful in developing a servo- actuated clutch and a carburetor. The result of our combined efforts was a retro-fitted hybrid scooter which was fully electric at speeds < 40 km/hr, fully IC engine powered between speeds 40-60 km/hr and a hybrid of both at speeds > 60 km/hr. This proved to be an exceptional approach in a country like India with a major part of the population still burning coal for heating homes.

Skills:

-

Hybrid architecture

-

MATLAB

-

Microcontroller programming

-

Advanced control system design

-

Team player

Award- “People’s choice” – Technovanza 2015

Unmanned autonomous base

I was part of a team developing a ROS based unmanned autonomous self-navigating base, using 2D LIDAR. My main contributions were in designing and developing the chassis and suspension components, developing a solenoid based brake mechanism for the BLDC motors, and modifying the mechanical structure to reduce localization errors.

Skills:

-

AutoCAD

-

Analytical

-

ROS programming

-

Power Electronics

OMRON LD autonomous bot

Working on the LD-90 unmanned autonomous base involved, getting in-depth knowledge of its system architecture and the Mobile planner application. I performed activities like mapping and adding “zones”, interfacing and controlling the base through an onboard Windows PC, Working with SICK lasers. Having expertise in diagnostics, I was also responsible for identifying drivetrain and suspension issues.

Skills:

-

Failure mode and effect analysis (FMEA)

-

Fish-bone analysis

-

Arduino programming

-

TCP/IP configuration

-

Sensor integration